| BB2 |

: |

BUCKLT

ELEVATORS :- |

|

|

Used for

vertical conveying of bulk material of various kinds and can be of

belt type or chain type. Different types of bucket profiles

are available for specific applications. Heights can be up

to 60 mtrs. And handling capacities is up to

500 TPH.

Back

|

| BB4 |

: |

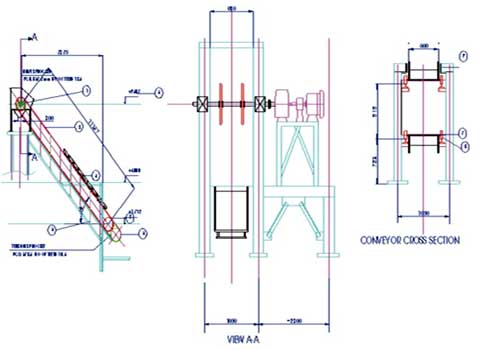

DEEP

BUCKET CONVEYORS :- |

|

|

Similar

to that of chain conveyors having buckets mounted on chains

with various profiles for carrying material horizontally and or

inclined. Advantages are to handled abrasive, hot

materials. |

|

1. Drive

Sprocket

2. Driven Sprocket

3. Chain

4. Bucket

5. Tensioning Unit

6. Supporting Structure

7. Bogie Wheel

8. Rail

9. Guide Angle |

|

Back

| BB5 |

: |

ROLLER

CONVEYORS :- |

|

|

Usually used

for material such as cartons, boxes, bales etc. wherein

rollers are

assisting the movement of the goods for easy handling. Can

also be motorized. |

Back

|